Track Removal

Railroad Track Removal

Track Removal Operations

Railroad Track Removal

Iron Horse is almost entirely funded from residual proceeds on our track removal operations. We are experts at track removal. Our personnel have removed well over 100 miles of track along all varieties of railroad corridors and environmental conditions. You are assured to be working with a professional, competent, and experienced organization that will lead to success in your project. Read on for more details on our track removal process.

Spikes and Tie Plates

Track Removal Operations

Railroad Track Removal

Spikes and tie plates have been removed from track. Water Truck standing by for torching operations to begin on the bolts that connect all the rails together.

Track Removal Operations

Track Removal Operations

Removal of Spikes and Bolts

The Nordco Superclaw, it quickly and efficiently pulls spikes allowing the railroad track to be moved for cutting.

Removal of Spikes and Bolts

Rail and Other Track Material

Removal of Spikes and Bolts

We have various ways to remove spikes and bolts. We select the appropriate methods for the site and materials. Ten to twenty thousand spikes are used per mile of track! Spike removal is the most important step in the track dismantling process. Our goals are safety, productivity, and maximizing any reuse purposes for the track materials. All spikes are also removed from scrap ties so the scrap ties may be ground and used in biomass power plants. IHPS has two hydraulic spike pulling machines to assist in the spike pulling effort.

Rail and Other Track Material

Rail and Other Track Material

Rail and Other Track Material

The rail is now ready to have the connecting steel bars removed. The bars are removed and all steel is picked up from the right of way leaving the ties clean and ready for removal. Rail and other steel is sorted and stacked or packaged for shipment.

Pictured: Torching fasteners at a switch turnout. Firewatch stands-by with “water buffalo” to assure safe operations.

Tie Removal, Site Development

Tie Removal

Ties Sorted and Transported

Ties Sorted and Transported

This is a lengthy process with over 2,500 large railroad ties per mile of track. The ties are carefully gathered and sorted based on their condition and potential future use. No tie material is left behind. Ties without reuse capability are picked up and packaged and used for fuel at biomass power generation plants. The rest of the ties are sorted, packages, and then loaded out by truck for reuse. Ties are never left behind or dumped!

Ties Sorted and Transported

Ties Sorted and Transported

Ties Sorted and Transported

Ties have been dug and removed from the track bed. They have then been sorted and bundled, ready for shipment. All tie material is removed from the site and the disposition is documented. Scrap ties are used to generate power at biomass power generation plants.

Site Restoration

Trail Development

Trail Development

Once the right of way is cleared, a walkthrough is done to pick-up any remaining small items. The ballast is left smooth and clean ready for use as a trail or to provide better site access for maintenance and other purposes. The track materials have been put to better use, and you have a more useful and productive real estate asset.

Trail Development

Trail Development

Trail Development

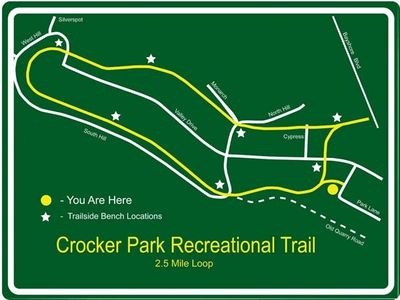

IHPS also provides rail trail improvements on some removal projects. The improvements may include extra grading and compaction work in spots as necessary, extra vegetation removal, signage, historical information, benches, waste receptacles, etc.

Copyright © 2020 Iron Horse Preservation Society, Inc. - All Rights Reserved.

Powered by GoDaddy Website Builder